When we encounter the acronym TPM Lean, we are essentially looking at several terms that are closely aligned. TPM (Total Productive Maintenance), sometimes understood as Total Productive Management, involves a comprehensive approach to machine and equipment maintenance to maximize production efficiency. In the context of Lean Management, this specifically involves using TPM audits to streamline Maintenance (UR) operations.

In this light, implementing Lean Management principles is not just a strategy but a necessity. Analyzing a specific case study, we see how deeply these principles are rooted in organizational culture. Based on a study by the Silesian University of Technology, it was proven that over 70% of employees in a printing company understood the management’s vision and were proficient in using Lean tools. This led to the TPM program being implemented for at least 70% of the machines, maintaining an average machine readiness rate above 80%.

Achieving such results requires regular audits that cover the entirety of TPM within the Lean framework. This article explains what a TPM audit is, why it is crucial, and which tools are most effective for its execution.

Among the wide range of Lean tools, Total Productive Maintenance (TPM) plays a vital role. It focuses on maintaining machine and equipment performance, which directly impacts the efficiency of the entire production process.

Implementing TPM requires a systematic approach and organization-wide commitment. It is a process of continuous improvement that brings measurable benefits: increased efficiency, lower costs, and higher production quality. Fundamental to TPM Lean is a shift in mentality from “that’s not my job” to “production is our collective responsibility.”

Lean Manufacturing is well-established in Poland. Research by the Lean Enterprise Institute Poland across over fifty companies reveals impressive results:

These numbers represent a transformation where Lean becomes a comprehensive strategy, leading to a ten-fold increase in employee-reported improvements.

A TPM audit is a systematic evaluation of the implementation and effectiveness of the TPM system.

Key components of the audit:

A study by the Rzeszów University of Technology in a manufacturing plant in the Podkarpackie region found that many machines failed to meet current safety standards. A TPM audit focused on a guillotine shear (NG-8) from 1979 revealed:

The audit team used a checklist based on Directive 2009/104/EC to document non-compliances, highlighting an urgent need for corrective actions.

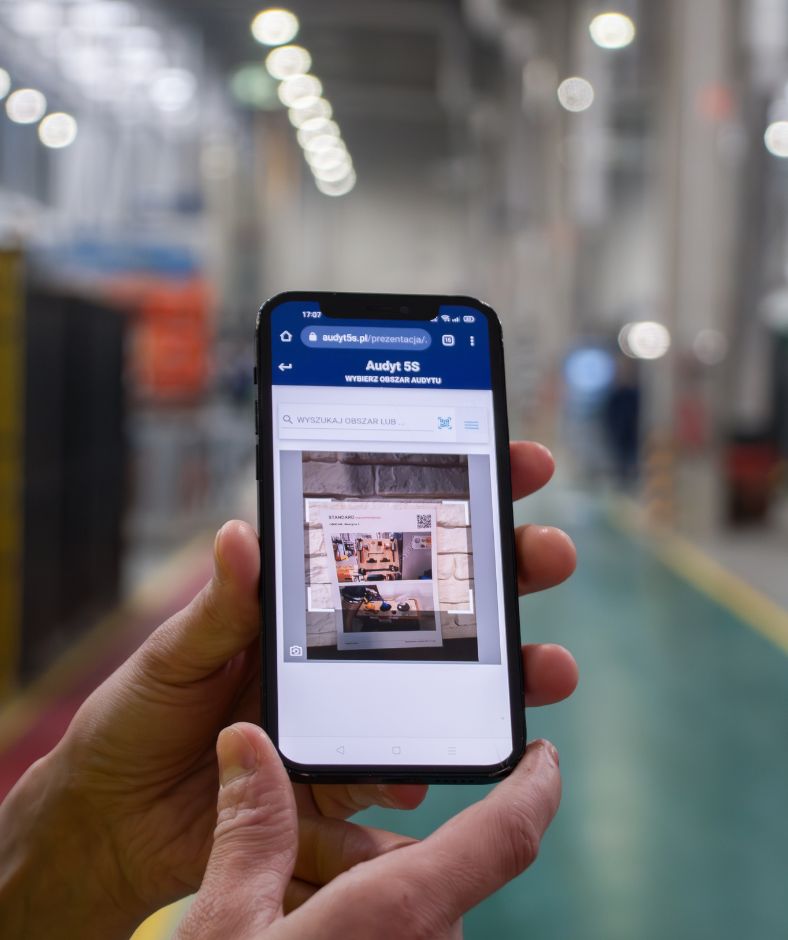

Conducting a TPM audit requires a systematic approach. Digital tools like auditomat® help optimize this process by replacing paper with flexible, data-driven solutions.

Key Features of a Digital TPM Audit System:

Conducting a TPM audit in a Lean context is vital for continuous improvement. It allows you to identify losses, monitor progress, and ensure safety.

Is your company fully utilizing the potential of TPM Lean? Don’t wait for breakdowns to occur. Use tools like auditomat® to take control of your production efficiency today.