Work standardization plays a key role in every organization, especially in the manufacturing sector, where it directly affects efficiency, quality, and process flow. Moreover, in a rapidly changing production environment, traditional approaches to work organization often prove insufficient. As a result, there is an urgent need to develop a new generation of work standards that are more flexible, modular, and easy to reconfigure. Such an approach enables companies to quickly adapt to changing production requirements without the need for costly and time-consuming reconfiguration of production line layouts.

At a certain point in time, Lodz University of Technology conducted a study involving a sample of 64 companies from various industries located in the Łódź region. The purpose of the study was to survey the use of work standardization within the selected group of companies and to understand whether it is currently a widely used tool or still requires particular attention from managers and future engineers. The results of the study allowed key conclusions to be drawn based on the percentage indicator confirming the implementation of standardization, where micro-enterprises accounted for 17%, small enterprises 32%, medium-sized enterprises 33%, and large enterprises 18%.

Taking these results into account, it is clear that standardization is progressing most rapidly in small and medium-sized enterprises. Therefore, this article focuses on analyzing the need to implement standardized procedures in manufacturing plants of small and medium-sized companies, as well as on methods for improving them. The aim of this article is to provide practical guidance and methodologies that support the effective implementation and continuous improvement of work standards in the manufacturing industry.

In its simplest form, work standardization is the process of documenting the steps of a work process, assigning roles, and defining the optimal sequence of these steps. Its purpose is to establish and maintain consistency. Moreover, work standardization forms the foundation of Lean Manufacturing, as well as all other continuous improvement programs. Work standardization ensures stability and reduces waste. It leads to increased operational efficiency and effectiveness, as well as greater job satisfaction among employees and managers.

A key element of effective standardization is the ability to identify and focus on the most important aspects of work. According to the Pareto principle, approximately 15–20% of tasks account for 80% of results. Therefore, when analyzing work processes, attention should be focused on these critical elements in order to achieve optimization and improve efficiency.

To better understand the concept, Lean is a management approach (commonly used in manufacturing and healthcare) that aims to eliminate all forms of waste in processes. Waste may include wasted or underutilized materials, time, talent, space, and anything else that does not deliver value to the customer. Since achieving lean operations requires the removal of unnecessary elements from all processes, work standardization itself is a key component in achieving this goal.

To avoid ambiguity, it is important to distinguish between three related terms:

Work standardization, as a foundation of Lean Manufacturing and continuous improvement, can be applied across a wide range of operational and organizational activities. Its purpose is to establish and maintain consistency, efficiency, and quality by precisely defining and documenting best practices.

Work standardization methods can be applied to:

In practice, job content varies significantly between companies and industries, as well as within a single organization. Some professions cannot always be clearly classified into specific job types. Employees often perform tasks of varying nature, combining routine activities with non-standard ones. The basis of this approach to standardization is breaking down the work process into component elements and identifying the knowledge and skills required to perform individual tasks.

The skills required to perform work can be divided into five categories:

A work instruction is a key standardization tool that enables process consistency and improved efficiency. Its development begins with dividing work into task categories, taking into account required skills and repeatability. It is important to distinguish routine tasks from non-standard and auxiliary tasks, focusing on those that generate added value.

Key stages in creating a work instruction include:

The goal is to create clear and precise instructions that minimize variability and facilitate employee training. Effective implementation of work instructions requires understanding how individual activities affect the efficiency of the entire process.

In the context of manufacturing, it is crucial to understand how the nature of a given process affects the possibility and scope of its standardization. The internal conditions that determine the level of standardization arise directly from the specific characteristics of the tasks being performed. Regardless of the industry or individual employee preferences, it is essential to identify those features of work that require a differentiated approach to standardization.

By analyzing work not in terms of specific job positions (e.g., assembler, machine operator), but rather in terms of its general characteristics, certain patterns can be identified that apply to any production environment. Ch. Perrow proposed a classification based on two key characteristics:

Based on these two characteristics, four types of work can be distinguished, each requiring a different approach to standardization:

Understanding these differences is crucial for the effective implementation of standardization in a production environment. It enables process optimization, increased efficiency, and improved production quality.

Understanding and implementing work standardization is essential for the effective functioning of enterprises, especially in the manufacturing sector. Standardization, understood as the process of documenting and unifying procedures, leads to increased efficiency, reduced waste, and improved quality.

Work standardization is indispensable for process optimization, efficiency improvement, and quality enhancement. Implementing standardized procedures—particularly in small and medium-sized enterprises—allows for better adaptation to changing market conditions and the achievement of a competitive advantage.

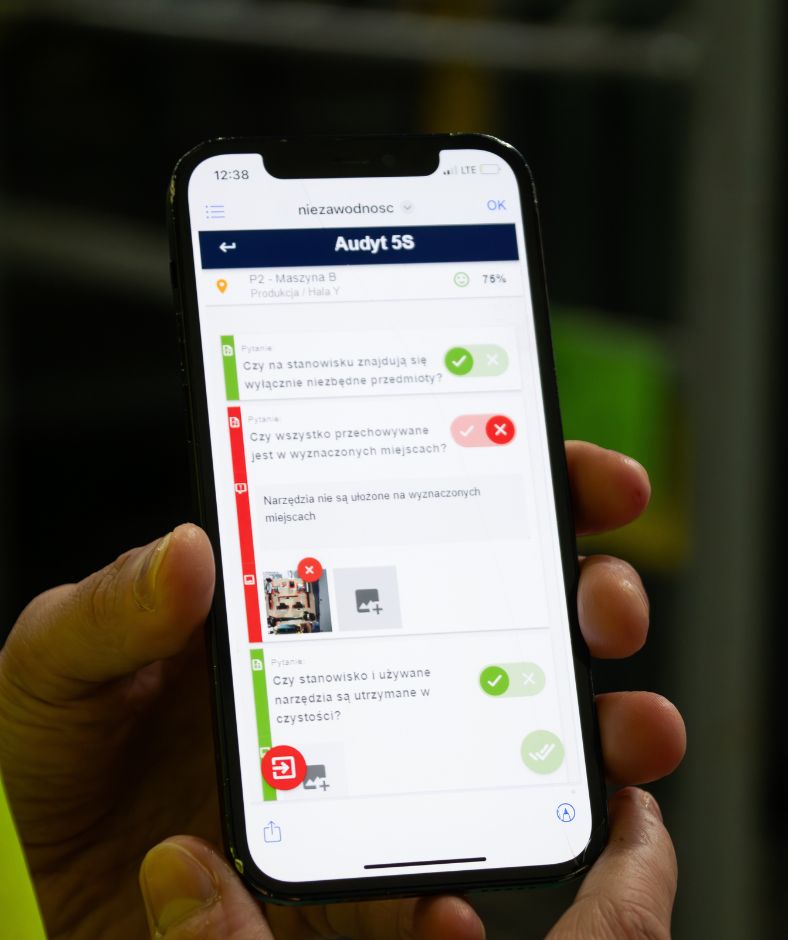

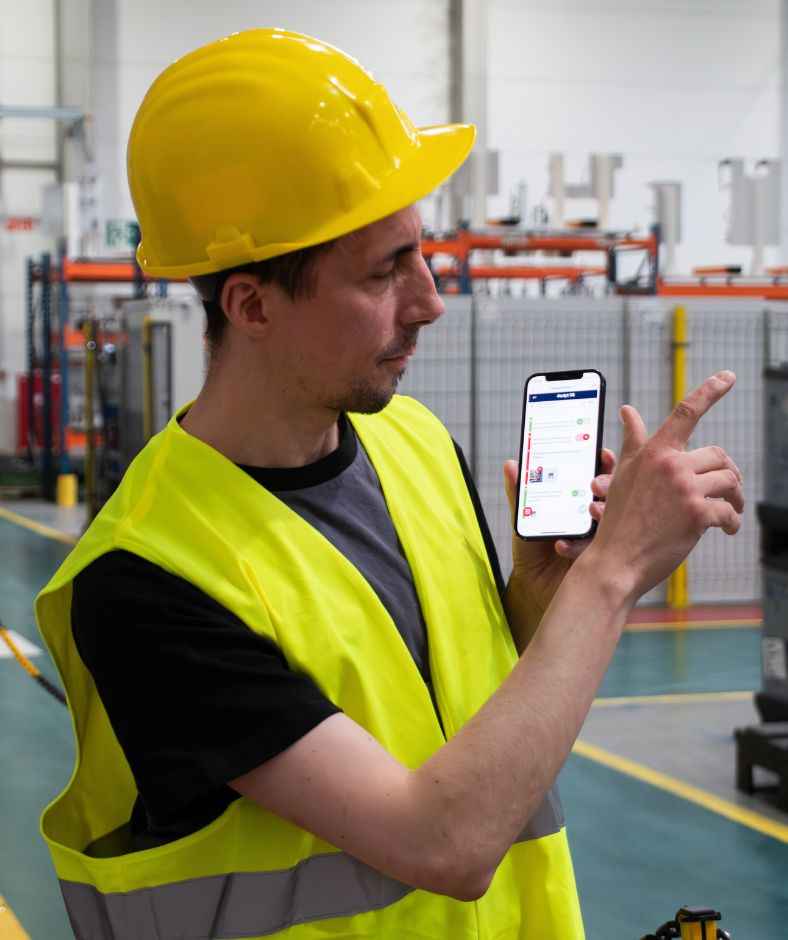

Do you want to improve audit processes and ensure compliance with the highest standards? Use modern auditing systems such as auditomat®, which help you effectively implement and monitor work standards. Discover how an auditing system can revolutionize your processes. Contact us today to learn more.