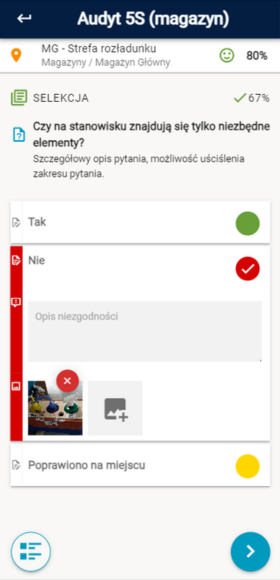

auditomat® streamlines Near Miss reporting through features like the "Quick Issue" module. This allows employees to easily report incidents without requiring login credentials, making it accessible to all employees, even those without work accounts or email access.

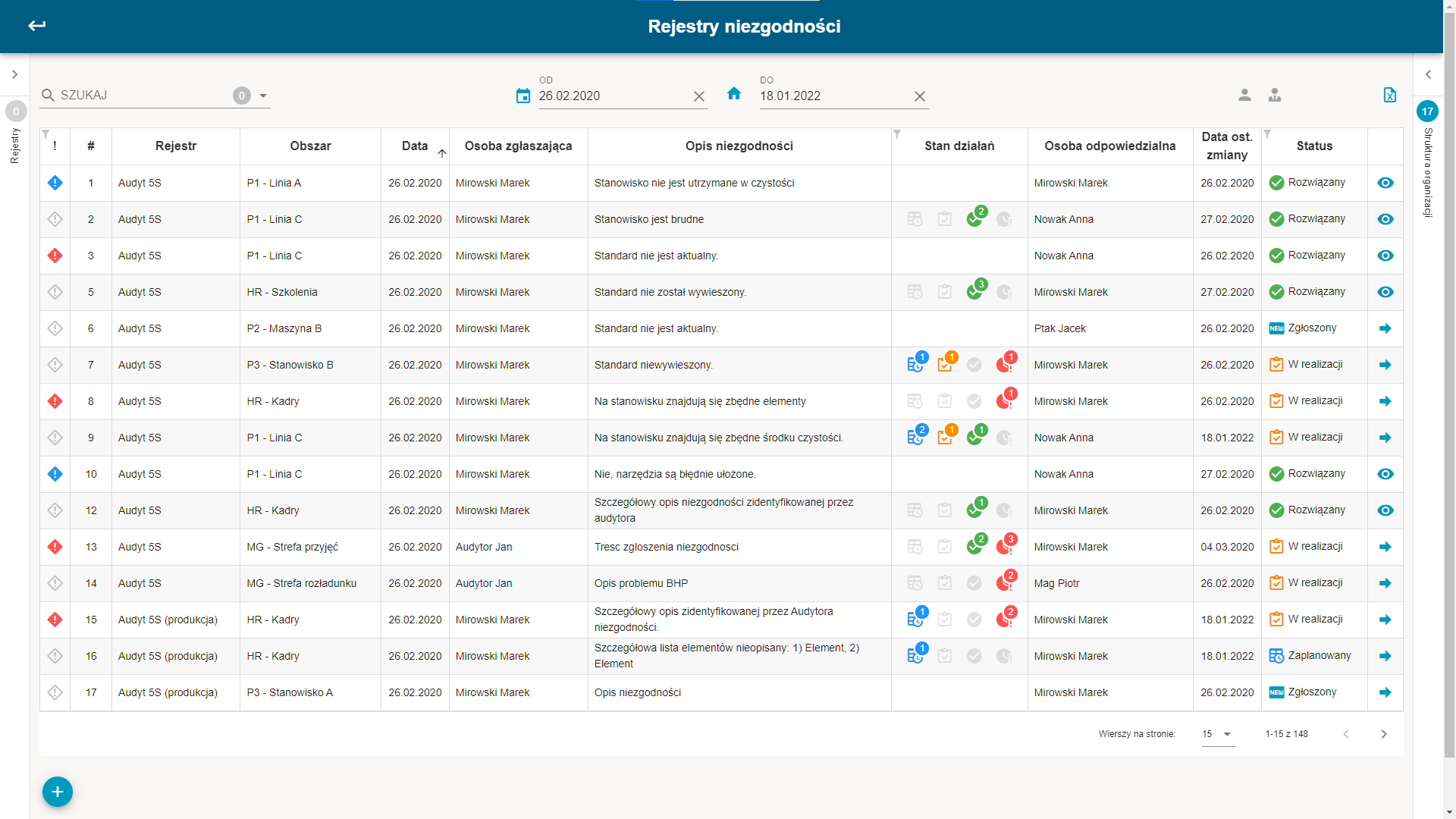

By simplifying the Near Miss reporting process and encouraging employee participation, auditomat® fosters a culture of safety. The accessibility and ease of use of the reporting system encourage employees to actively identify and report potential risks, ultimately contributing to a safer work environment.

The "Quick Issue" module allows for rapid and intuitive reporting of Near Miss incidents. Employees can quickly describe the situation without the need for complex login procedures, ensuring that potential hazards are reported promptly.

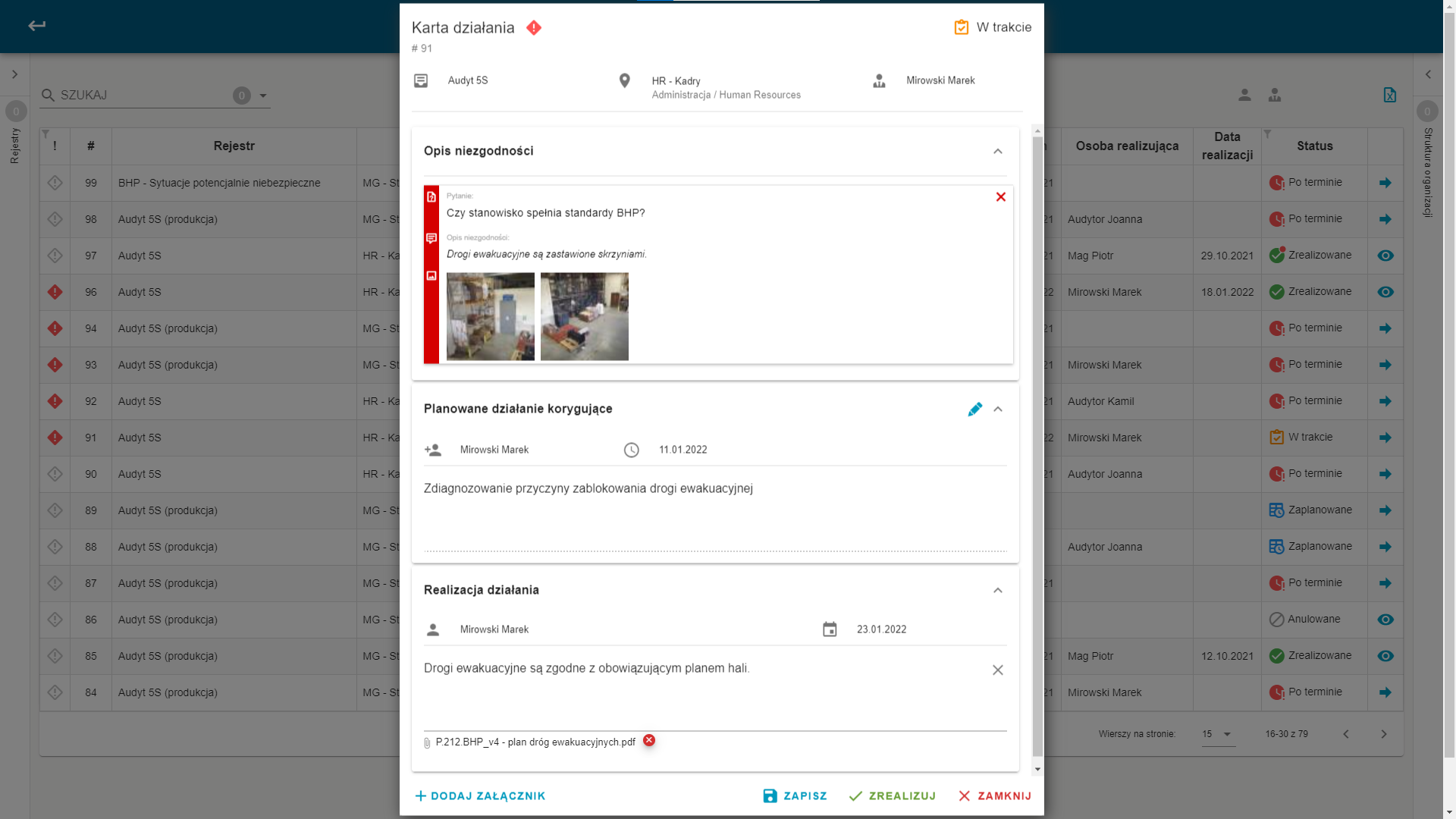

By automating data collection and enabling immediate forwarding of reports to relevant personnel, auditomat® facilitates a rapid response to potential problems. This allows for timely implementation of corrective and preventive measures, minimizing the risk of future incidents.

Employee participation in the Near Miss reporting process is crucial for improving safety standards. By actively identifying and reporting potential hazards, employees contribute to a safer work environment, while also increasing their own confidence and awareness of safety issues.