auditomat® supports the execution and documentation of audits across various aspects of production, including individual production lines, workstations, and machines. This enables the monitoring of process compliance with established quality standards. Furthermore, the system facilitates detailed analysis and quality audits of the produced products themselves.

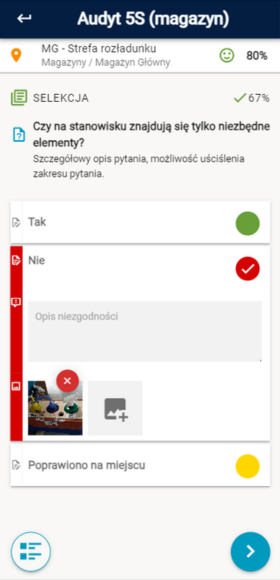

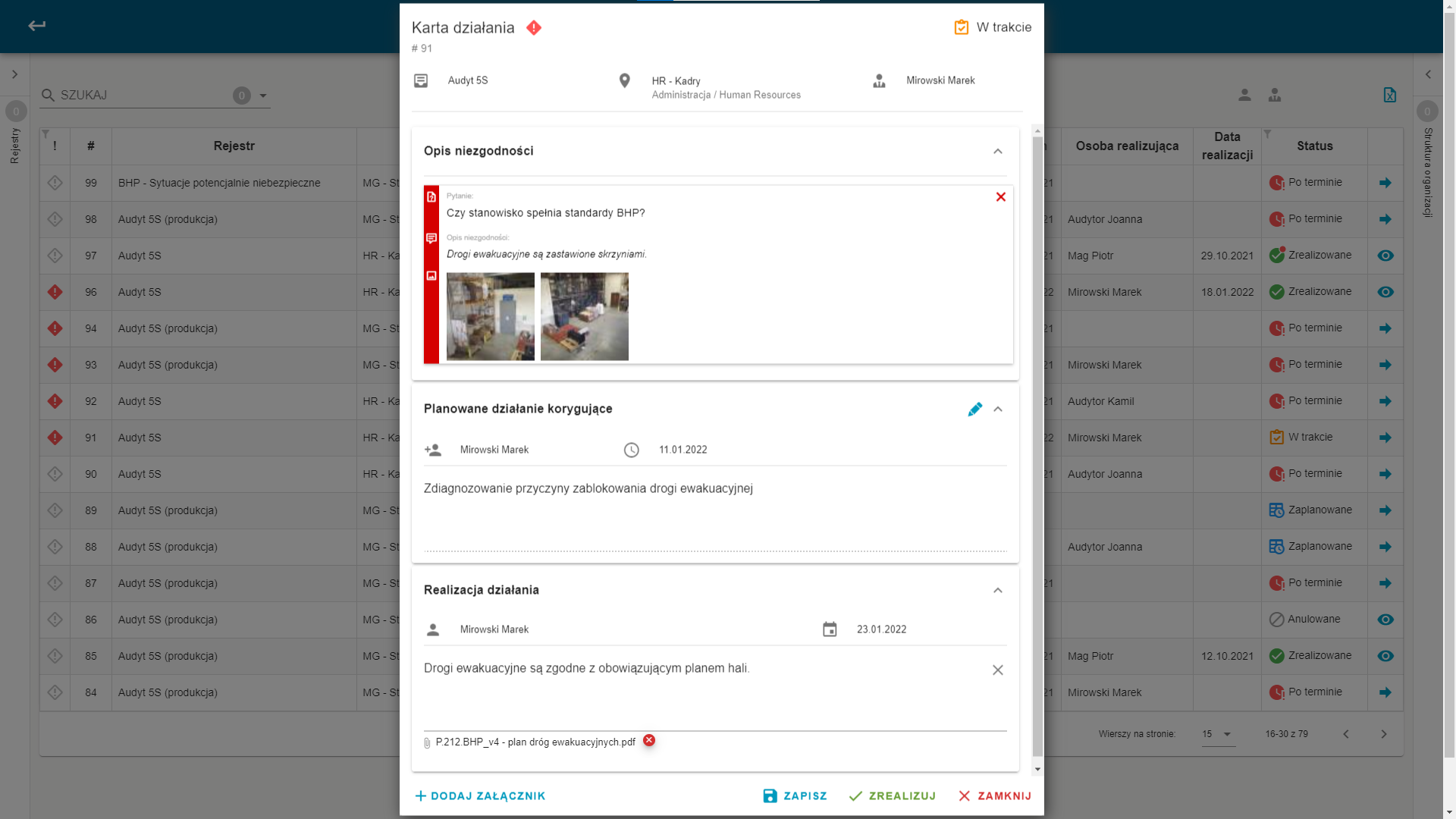

All identified nonconformities are automatically entered into appropriate registers within auditomat®. This enables effective planning and real-time monitoring of corrective actions, eliminating delays in addressing quality issues.

auditomat® allows for dedicated registers to be maintained for critical nonconformities, such as those requiring immediate production stoppage. The system enables detailed recording of critical incidents, including location, product details, and the cause, facilitating thorough analysis and the implementation of effective corrective actions to prevent recurrence.

By centralizing data collection and enabling advanced analysis, auditomat® provides valuable insights into quality performance. This historical data combined with real-time monitoring allows for continuous improvement of quality management systems and operational processes, enabling organizations to adapt effectively to changing internal and external conditions.

auditomat® extends beyond traditional audits by allowing for the recording of nonconformities, problems, and improvement ideas from any authorized individual. This broader perspective ensures a comprehensive approach to quality control and continuous improvement within the organization.